Mold 356-120-TC for Precision Reloading and Hunting Ammunition

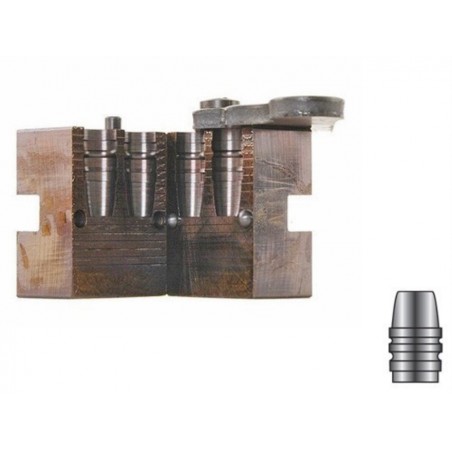

LEE 2-Cavity Bullet Mold specifically engineered for 9mm caliber applications.

Precision-crafted to produce .356 diameter, 120-grain truncated cone (TC) bullets with a flat point profile, ideal for 9mm Luger, .38 Super, and .380 ACP cartridges.

Featuring a ballistic coefficient of .123, these bullets offer optimized aerodynamic performance for enhanced accuracy and terminal ballistics in handgun shooting and metallic reloading.

LEEs 2-cavity bullet molds are an excellent choice for handloaders and ballistic enthusiasts seeking high-quality molds at a competitive price point, combining durability with precision casting capabilities.

Constructed from corrosion-resistant aluminum alloy blocks, these molds provide superior thermal conductivity compared to traditional iron or steel molds, allowing for faster heating and cooling cycles during the bullet casting process.

The aluminum construction also reduces overall mold weight by approximately one-third, minimizing operator fatigue during extended casting sessions and improving handling ergonomics.

The mold halves are securely clamped together using robust wooden-handled tongs, ensuring zero movement or misalignment when closed, which guarantees consistent bullet dimensions and quality with each pour.

Note that final bullet weights may vary slightly depending on the specific lead or lead alloy composition used in the casting process, affecting density and hardness.

The included tongs feature comfortable wooden grips for safe and efficient mold manipulation, enhancing user control and safety during high-temperature operations.

An integrated sprue cutter is incorporated into the mold design, serving as a precise lead gate to efficiently sever the bullet from the molten lead reservoir, ensuring clean separation and minimal post-casting cleanup.

For optimal mold longevity and bullet quality, it is highly recommended to thoroughly degrease the mold prior to initial use. Additionally, seasoning the mold by smoking or applying specialized mold release agents will improve bullet release and reduce surface imperfections.

Under no circumstances should the interior cavity of the mold be lubricated, as this can adversely affect bullet surface finish and dimensional accuracy.

Light lubrication of the sprue cutter screw is advised to maintain smooth operation and prevent corrosion, ensuring consistent sprue trimming performance over time.