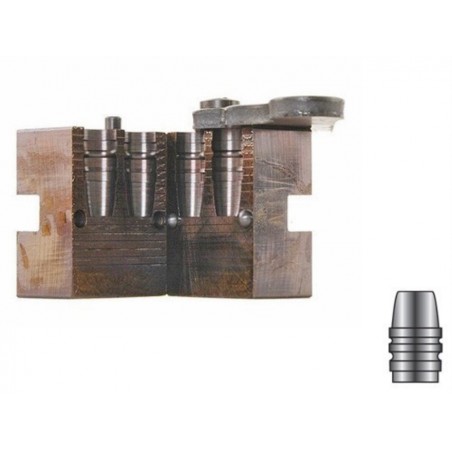

Mold C358-158-SWC for Precision Bullet Casting and Reloading

Lee Two-Cavity Bullet Mold for .38 Special and .357 Magnum Calibers

Designed specifically for precision handloaders and ballistic enthusiasts, this Lee bullet mold produces high-quality projectiles with a diameter of .358 inches, weighing approximately 158 grains. The mold casts Semi-Wadcutter (SWC) style bullets optimized for use with gas-checks, ideal for both .38 Special and .357 Magnum cartridges, ensuring superior accuracy and consistent ballistic performance.

Featuring a ballistic coefficient of .117, these bullets provide reliable external ballistics suitable for target shooting, hunting, and competitive shooting disciplines where precision and repeatability are paramount.

Constructed from durable, corrosion-resistant aluminum alloy, Lees two-cavity molds offer an excellent balance between longevity and ease of use. Aluminum molds heat up rapidly and cool down faster than traditional iron or steel molds, significantly reducing cycle times during bullet casting sessions and improving overall efficiency for reloaders.

Due to their lightweight designapproximately one-third the weight of comparable iron or steel moldsthese molds reduce operator fatigue during extended casting periods, making them ideal for both novice and experienced casters.

The mold halves are securely fastened with robust wooden-handled clamps, ensuring tight closure and consistent bullet dimensions with every cast. This design minimizes lead leakage and enhances the uniformity of each projectile.

Note that the bullet weights produced may vary slightly depending on the specific lead alloy composition used, a common consideration in metallic and semi-metallic bullet casting processes.

Equipped with an integrated sprue cutter blade, the mold facilitates clean separation of the molten lead from the bullet cavity, allowing for smooth release of finished projectiles and minimizing post-casting cleanup.

The package includes a pair of durable tongs for safe and efficient mold handling during the casting process.

For optimal performance and mold longevity, it is highly recommended to thoroughly degrease the mold before initial use. Additionally, seasoning the mold by smoking or applying a specialized mold release agent will enhance bullet release and prevent lead buildup, ensuring consistent casting quality over time.

.jpg)