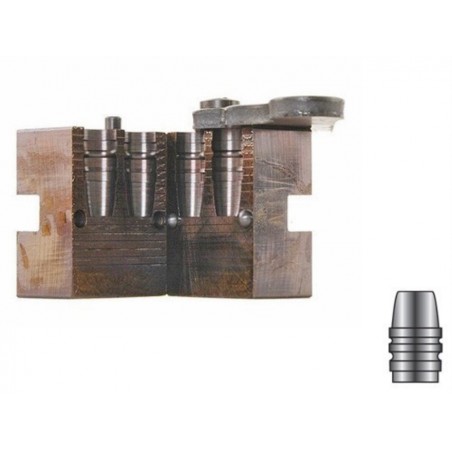

Mold C429-240-SWC for Reloading and Casting Bullets

Lee Two-Cavity Bullet Mold for .44 Magnum, .44 Special, and .44/40 Calibers

Designed for precision casting, this Lee bullet mold features two cavities optimized for producing high-quality projectiles suitable for .44 Magnum, .44 Special, and .44/40 cartridges.

Each cavity casts bullets with a diameter of .429 inches, weighing approximately 240 grains. The mold produces Semi-Wadcutter (SWC) style bullets specifically designed for use with Gas-Check applications, enhancing performance and reducing barrel leading.

The bullets cast with this mold have a ballistic coefficient of approximately 0.124, providing reliable external ballistics for medium-range hunting and target shooting scenarios.

Lees two-cavity molds are an excellent choice for reloaders and ballistic enthusiasts seeking a cost-effective, durable solution for metallic and semi-metallic bullet casting. These molds offer a balance between quality craftsmanship and affordability, making them ideal for both novice and experienced handloaders.

Constructed from corrosion-resistant aluminum alloy, these molds provide superior thermal conductivity compared to traditional iron or steel molds. This allows for faster heat absorption and cooling cycles during casting, resulting in improved bullet consistency and reduced cycle times.

The lightweight aluminum construction reduces operator fatigue during extended casting sessions, weighing approximately one-third less than comparable iron or steel molds. This ergonomic advantage is particularly beneficial for reloaders producing large quantities of projectiles.

The mold halves are securely held together by sturdy wooden-handled tongs, ensuring precise alignment and ease of handling throughout the casting process. This robust clamping mechanism minimizes flash and guarantees uniform bullet dimensions.

It is important to note that the actual bullet weights may vary slightly depending on the lead alloy composition used during casting, necessitating careful measurement and load development for optimal ballistic performance.

An integrated sprue cutter blade facilitates efficient lead flow and clean separation of finished bullets from the mold, streamlining the casting workflow and reducing post-casting cleanup.

The mold package includes high-quality tongs for safe and comfortable operation.

For best results, it is highly recommended to thoroughly degrease the mold prior to initial use. Additionally, seasoning the mold by smoking or applying a specialized mold release agent will enhance bullet release and extend mold life.

.jpg)