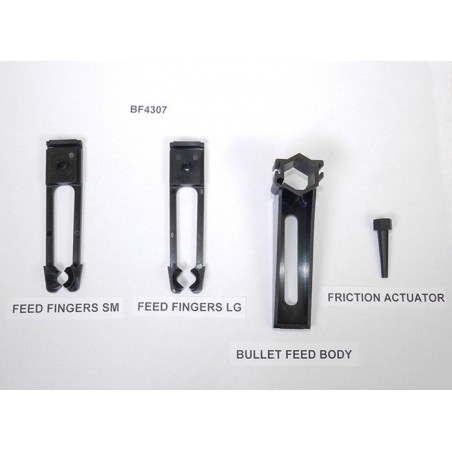

BF Kit Molded Components for Hunting, Shooting, and Reloading

The BF Kit Molded Parts represents a meticulously engineered assembly designed for precision-driven metallic and semi-metallic reloading applications. Crafted from high-grade polymer composites, these molded components ensure exceptional durability and dimensional stability under rigorous shooting and reloading conditions. Each part within the kit is optimized to enhance the efficiency and reliability of your reloading process, providing seamless integration with standard caliber dies and press systems.

Specifically tailored for competitive shooters and ballistic enthusiasts, the BF Kit Molded Parts delivers superior resistance to wear and thermal deformation, critical factors when handling high-pressure cartridges. The kits design incorporates ergonomic features that facilitate rapid assembly and disassembly, reducing downtime during extended shooting sessions. Additionally, the parts exhibit excellent chemical resistance against primers, powders, and lubricants commonly used in metallic and semi-metallic cartridge fabrication.

Utilizing advanced injection molding techniques, the BF Kit ensures consistent tolerances that contribute to uniform bullet seating depth and primer pocket preparation, essential for achieving optimal ballistic performance and accuracy. This precision manufacturing process also minimizes material waste, aligning with sustainable reloading practices.

Whether you are refining your handloading setup for hunting, tactical training, or precision target shooting, the BF Kit Molded Parts provides a robust foundation for enhancing your ammunition assembly workflow. Its compatibility with a wide range of calibers and reloading presses makes it an indispensable component for reloaders seeking to maximize cartridge consistency, velocity control, and overall shot-to-shot uniformity.