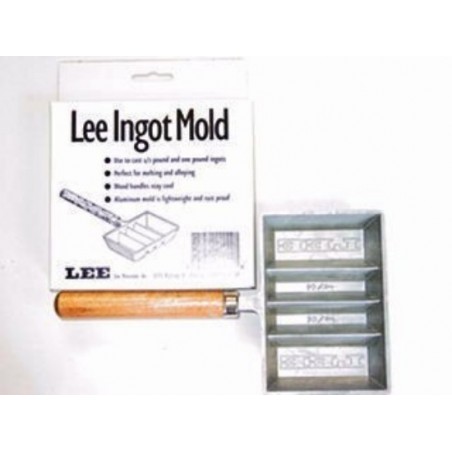

Mold Pliers for Reloading and Precision Shooting

Precision-engineered handles specifically designed for Lee 6-cavity bullet molds that are originally supplied without handles. These tenacious grips provide enhanced control and safety during the casting process, ensuring consistent and reliable bullet production for metallic and semimetallic ammunition reloading applications.

Additionally, these durable handles are fully compatible with Lyman bullet molds featuring 1 or 2 cavities, offering versatility for reloaders who utilize multiple mold brands and configurations. Their ergonomic design facilitates optimal heat dissipation and secure handling, critical factors in high-volume bullet casting operations.

Constructed from high-grade steel combined with premium hardwood, these handles deliver exceptional durability and resistance to thermal stress and mechanical wear. The robust steel core ensures structural integrity under repeated thermal cycling, while the hardwood exterior provides a comfortable, non-slip grip, minimizing operator fatigue during extended casting sessions.

Ideal for precision shooters and reloaders focused on maximizing ballistic performance through custom bullet fabrication, these handles enhance mold manipulation, reduce casting defects, and improve overall workflow efficiency in metallic and semimetallic bullet production.

90005 Lee Commercial Mold Handles from Lee Precision on Vimeo.