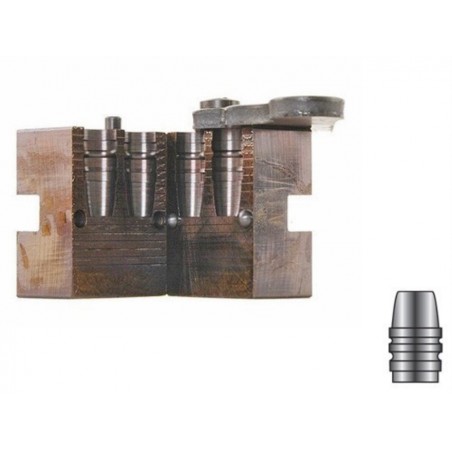

6 Cavity Mold 452-230-TC for Bullet Casting (Tongs Not Included)

LEE 6-Cavity Bullet Mold specifically engineered for .45 ACP, .45 Auto Rim, and .45 Colt (Long Colt) calibers, designed to optimize precision casting in metallic and semi-metallic bullet reloading processes.

This mold produces bullets with a diameter of .452 inches and a weight of 230 grains in a truncated cone (TC) profile, ideal for achieving consistent ballistic performance and reliable terminal ballistics.

Compatible with popular handgun cartridges such as .45 ACP, .45 Auto Rim, and .45 Colt (Long Colt), this mold is tailored for shooters and reloaders seeking high-quality, uniform projectiles for target shooting, self-defense, or competitive applications.

Featuring a ballistic coefficient (BC) of approximately 0.146, these bullets offer a balanced trajectory and energy retention suitable for a wide range of shooting disciplines.

Constructed for high-volume production, this bullet mold facilitates efficient casting of lead and lead-alloy projectiles, enabling reloaders to maintain consistent output during extended casting sessions.

The mold block is precision-machined from high-grade aluminum, incorporating steel bushings and corrosion-resistant alignment pins to ensure durability, precise cavity alignment, and extended service life under rigorous use.

Aluminum construction provides superior thermal conductivity compared to traditional iron molds, allowing for faster heat-up and cooldown cycles. This thermal efficiency reduces downtime between pours and helps maintain optimal casting temperatures, resulting in superior bullet quality and reduced porosity.

Additionally, the aluminum mold is approximately one-third lighter than iron counterparts, significantly reducing operator fatigue during prolonged casting operations and enhancing handling ergonomics.

The two aluminum blocks are securely clamped using specialized bullet mold handles (not included), preventing any lateral or vertical movement during the molten lead pour, which is critical for producing perfectly formed and dimensionally consistent projectiles.

This mold features an anodized, extra-hard sprue plate that functions as a pour basin, sprue cutter, and bullet trimmer. The hardened surface ensures a clean, precise cut of the sprue, minimizing post-casting cleanup and optimizing bullet uniformity.

Note that bullet weights may vary slightly depending on the specific lead alloy composition and casting parameters used.

Bullet mold handles for opening and closing the mold are sold separately under reference number 90005.

For optimal performance and longevity, it is highly recommended to thoroughly degrease the mold before initial use. Additionally, applying a light coating of mold release agent or seasoning the cavities with smoke from a candle or similar source helps prevent lead adhesion and facilitates easier bullet removal.

Never lubricate the interior cavity surfaces, as this can degrade bullet quality and cause mold damage.

Apply a light film of lubricant to the sprue plate retention screw to ensure smooth operation and prevent seizing during repeated use.